How to Use a Desoldering Pump

Introdução

Ir para o passo 1A desoldering pump (or solder sucker) is a handy tool that sucks molten solder. You can use it to desolder through-hole components on a circuit board or to rework bad solder joints.

This guide shows how to use and clean iFixit’s desoldering pump. You may need to use some soldering wick to clean up any solder remnants—follow this guide on how to use soldering wick.

O que você precisa

-

Ferramenta utilizada neste passo:Desoldering Pump$3.99

-

Firmly grasp the desoldering pump with your hand.

-

Depress the plunger until it locks in place.

-

-

Ferramenta utilizada neste passo:Solder Wick Braid$4.99

-

Prime the desoldering pump by depressing the plunger.

-

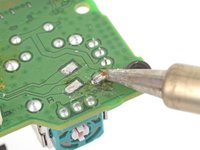

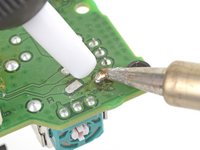

Heat the solder joint until the solder is liquified. To help with heat transfer, add some solder onto the soldering iron's tip.

-

Position the pump's nozzle as close to the molten solder as possible.

-

Press the side button to activate the pump.

-

Repeat the process until the joint is clean. You can also use solder wick to help soak up any remnant solder.

-

-

-

To clean the pump, prime and activate the pump a few times. This pushes a rod through the nozzle and ensures that solder doesn't block it.

-

Grasp the nozzle by its knurled edge.

-

Twist the nozzle counter-clockwise to unscrew it. This may be difficult due to a tight-fitting O-ring.

-

Remove the nozzle and clean out the pump interior.

I hadn’t used my pump for a while so it wasn’t zooming up the tube like it used to (despite numerous tries). So, I simply unscrewed the nozzle and dripped a bit of fine oil into the tube. I replaced it and operated it a couple of times…BINGO….best it ever worked. I was totally surprised and glad I didn’t have to buy a replacement. BTW - I happened to have some Starrett tool oil on hand and that’s what I used. Any thin oil should be fine and you don’t need very much.

That’s a great tip Keith!

What is the best way to clean sthe older with when it is in the pump?

-

For soldering instructions and tips, follow this guide.

For soldering instructions and tips, follow this guide.

Cancelar: não concluí este guia.

78 outras pessoas executaram este guia.

Gear Up For Future Repairs

Shop all4Comentários do guia

Good review, but I’ve found that these small solder suckers don’t do a very good job. The much larger “Soldapult” (https://www.edsyn.com/product/DS017.html) provides much more suction and can often completely clear a joint in one use.

How does the tip not melt.

Apply higher temperature on your soldering iron, above 380°C.

Use bigger tip, bigger heating surface provides more effecitive heat transfer.

If you are asking about why the tip of the solder sucker doesn't melt, it is made of a heat resitant material. Notice the word resistant.