Hi @oldturkey03

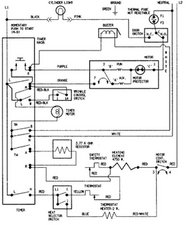

The wiring diagram doesn't show a capacitor in the motor circuit, so I'm wondering if the start winding (aka aux in the diagram) is open circuit or the motor's centrifugal switch is faulty.

@tonedub ,

It is hard to test the motor's two windings for continuity unless you open the motor and access the individual windings.

You may be able t do this from the back of the motor terminal block but I'm not sure.

If you have a DMM (digital multimeter) you may be able to use its Ohmmeter function and measure the motor’s start and run windings for continuity at least.

Disconnect the power from the machine and then take a picture of the harness wiring connections to the motor. This is so you can reconnect them correctly afterwards.

According to the wiring diagram there are only 3 wires, purple, orange and white (although there may be a 4th green wire on the motor chassis, which is an earth)

You won't know if it is the winding or the centrifugal switch which is in the start winding circuit unless you can also access the centrifugal switch as well.

The switch is internal to the motor and what happens is that when the motor is at rest then both the start and run windings are in circuit. When power is applied current flows through both windings and this creates sufficient magnetism to cause the motor to overcome the initial inertia and to rotate. When the motor runs up to speed, the centrifugal switch operates and disconnects the start winding allowing the motor to rotate on the run winding only.

If the start winding circuit i.e. start winding or switch is faulty there will be a humming sound as the motor is trying to turn on the run winding only but can't as insufficient magnetism is produced to overcome inertia from the at rest position.

The start winding has only very thin wires and heats up quickly so you don't want it in circuit for longer than necessary and possibly burn out, ( does the motor have a burnt smell?). The run winding has thicker wires allowing the motor to run for long periods.

Like most things, rewinding motors is a skill and you also need the correct parts and equipment if one is faulty e.g. correct size wire or switch etc. Also you need to know how many turns of wire are needed etc etc so not easy at all for a DIY repair. If the motor is faulty then you may be able to get it repaired cheaper than buying a replacement but this may depend if you have motor rewind repairers in your location and how much they charge.

3

3

374

374  1,5 mil

1,5 mil